Flexible and adaptable.

melt is the classic ELESGO clean touch surface with a hot-melt adhesive coating on the reverse side. It’s the perfect product for carpenters and booth constructors, as well as for use in interior fittings.

melt

Furniture

Worktops

Interior doors

Adhesive surfaces

The back of the classical ELESGO clean touch surface is coated with a hot melt adhesive. This enables compressed wood board such as HDF or MDF to be laminated using standard veneer, moulding, or continuous roll laminating presses. It allows you to produce an infinite number of panel formats with minimal surface waste.

This enables you to easily apply well-known ELESGO clean touch properties, such as soft touch, anti-fingerprint, mechanical resilience, and much more to your product. In addition, the ELESGO melt surface covers small imperfections due to its almost reflection-free appearance.

ELESGO surfaces are optionally

Highly scratch-resistant

Abrasion-resistant

Fade-resistant

Dirt-resistant

Equipped with outstanding tactile properties

Based on a fully cross-linked EBC surface

On continuous roll laminating and double-belt presses

Working width from 1,200 mm to max. 1,600 mm width

Using variable panel materials (HDF, MDF, PVC, etc.)

Weight: ~ 260–280 g/m²

Scratch resistance: Level 3

Gloss level: ~ 3 ± 2

(60° angle)

Dirt resistance:

Group 1 Level 4

Group 2,3 Level 5

Release Film type: PET

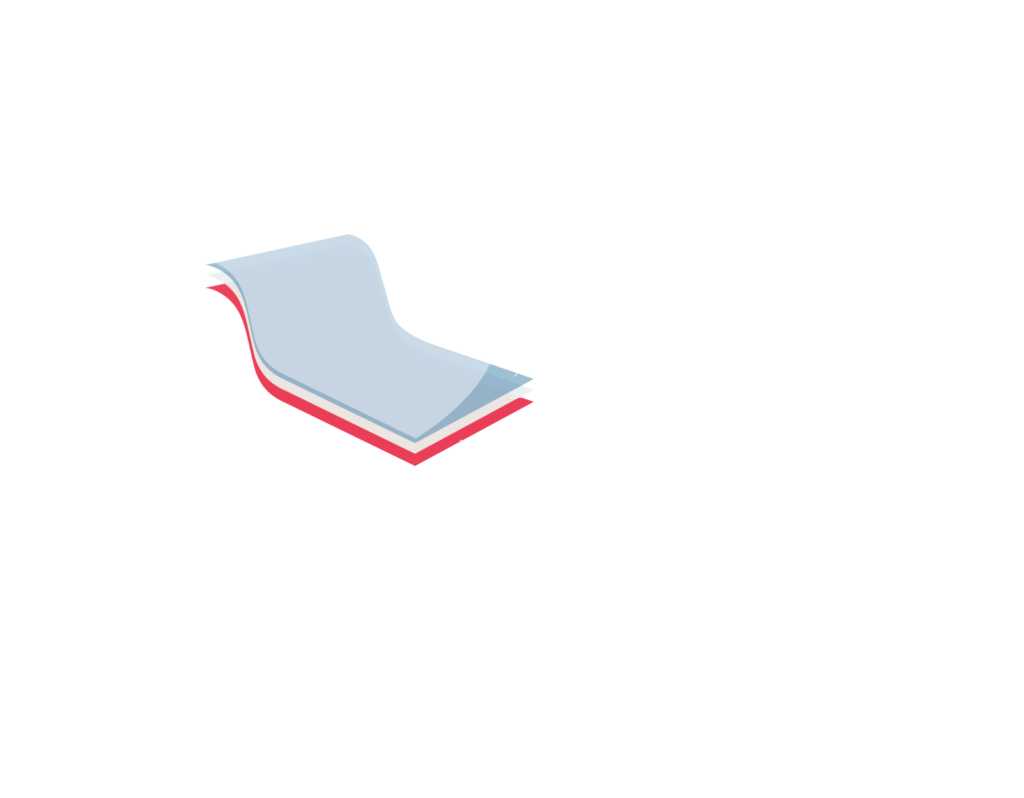

Surface construction

What makes the ELESGO melt surface unique is the combination of EBC coatings. These coatings are applied in several layers to the substrate and cured with our patented EBC manufacturing process. The EBC technology gives the surface an extremely long life in addition to its outstanding tactile and visual properties.

Thanks to the hot-melt adhesive applied to the back, melt is particularly easy to handle during further processing. The scratch- and abrasion-resistant surface can be processed easily and bubble-free using a conventional veneer and moulding press or a roll hot laminating machine.