Let´s surface your future.

We’ll work with you to design the perfect ELESGO surface for your product. Individualised for your workflow, realised with our many years of know-how.

EBC technology

One technology.

So many possibilities.

The crosslinking of coating systems using electron beams opens up a wide range of possibilities. All the while we are constantly researching to widen our application areas as well as to add further properties to our ELESGO surfaces. Our goal is to use this flexible technology to further customise our surfaces according to our customers requirements.

Whether it’s our soft touch feel or other technical surface requirements, EBC technology has few limitations.

Numerous production advantages

Our environmentally friendly production process, which uses electron beam technology, excels through its exceptionally low energy intake. It is also entirely emission-free . The production process, which is completely free of solvents and formaldehyde, offers superb working conditions for our production workers.

Every product we manufacture is characterised by an extremely long service life, even under the most demanding conditions. ELESGO surfaces are fully cross-linked. They are scratch resistant, nearly odourless, and easy to clean. These properties are due to the unique coating formulation we use in their production.

The transfer of microscopic textures gives each surface a wide range of properties customised to its respective area of application – from super-matt to high-gloss to anti-fingerprint.

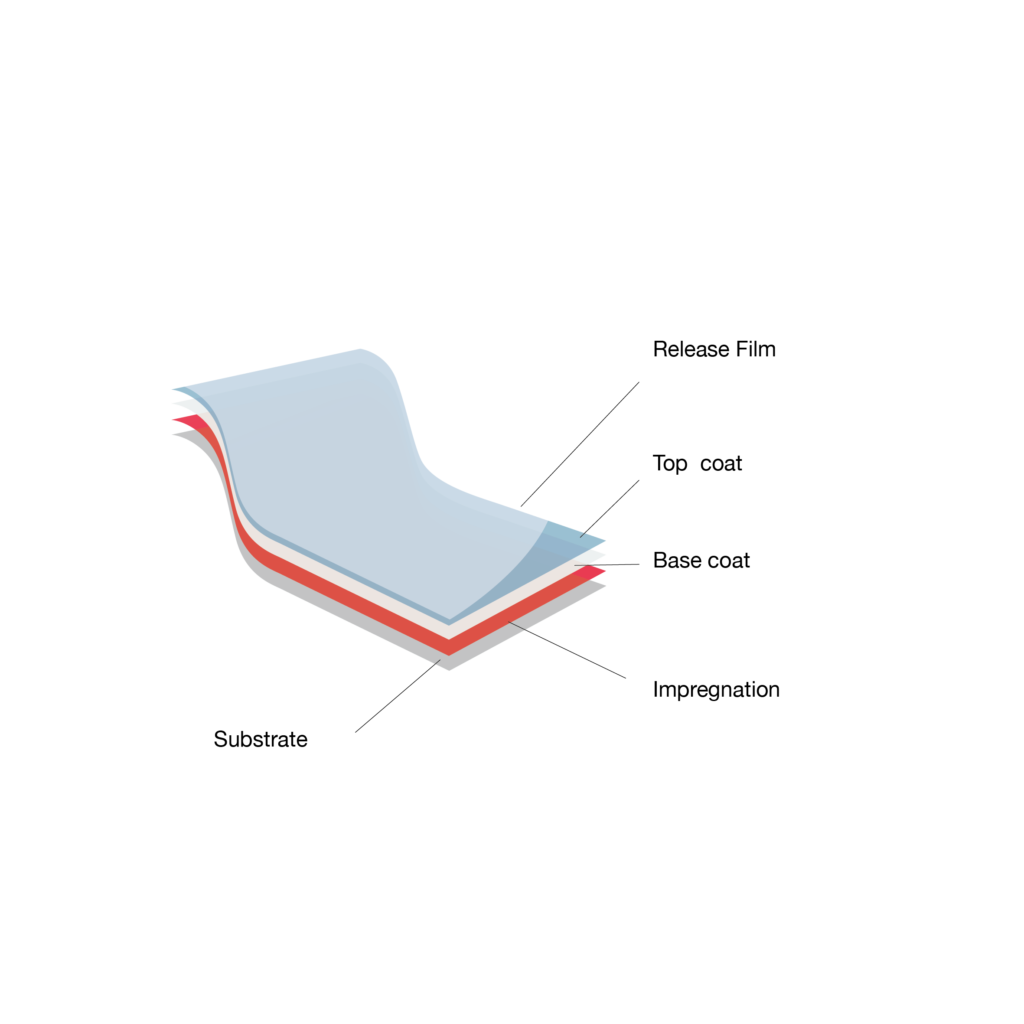

Surface construction

Each ELESGO surface is composed of the impregnation coating, the base coating, and the top coating. These are applied to the carrier material one after another and cured using electron beams in a unique manufacturing process. The EBC technology gives the surface an extremely long life.

The transparent-coated printed patterns or pigmented papers are just one of the factors which determine the surface’s final appearance. We make (almost) anything possible to create a surface tailored precisely to your requirements.

These surfaces can then be applied to a wide variety of substrates or further processed into HPL and CPL laminates.

A release film transfers the special look and feel to the ELESGO surface. This film can remain in place to protect the surface until the finished product is installed, then is simply peeled off. This is how your customised surface is created.